CAPA: finding the perfect balance between preventive and corrective actions

Both corrective actions and preventive measures are necessary to efficiently manage a production plant. In this article, we explain how you can make use of the CAPA system to find the perfect balance in your industrial maintenance department. In the maintenance...

CAPA: finding the perfect balance between preventive and corrective actions

Both corrective actions and preventive measures are necessary to efficiently manage a production plant. In this article, we explain how you can make use of the CAPA system to find the perfect balance in your industrial maintenance department. In the maintenance...

More articles

CAPA: finding the perfect balance between preventive and corrective actions

Both corrective actions and preventive measures are necessary to efficiently manage a production plant. In this article, we explain how you can make use of the CAPA system to find the perfect balance in your industrial maintenance department. In the maintenance...

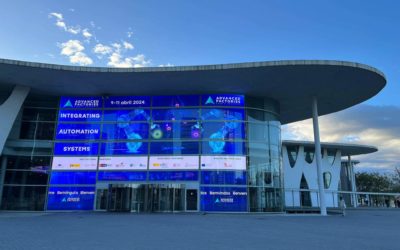

Mapex presents the benefits of its MES solution at Advanced Factories 2024

From April 9 to 11, we participated as exhibitors at Advanced Factories, one of the most important events in the field of digitization and industrial automation in our country. Last day of the eighth edition of Advanced Factories in the Gran Via exhibition center of...

Process standardization: how can digitization help you achieve your goals?

Process standardization is the cornerstone of any improvement in the manufacturing industry. In this article we explain what this methodology consists of, what its benefits are and how you can use Mapex to implement it effectively in your factory. What is process...

MES technology to address major challenges shared by industrial companies

Achieving production targets, improving the bottom line, satisfying customers and complying with legal regulations. These are four of the major pain points shared by most industrial companies. In this article, we show you how you can address all these issues with the...

Identify and eliminate the root cause of bottlenecks with the help of an MES system

The first step to improve production flow is to identify and analyze the causes of bottlenecks in your operations. An MES system allows you to obtain real-time visibility of your processes, something that will undoubtedly help you detect and eliminate these types of...

Saving water in the factory: how to deal with restrictions and reduce costs

Read on if you want to keep your factory's water consumption in check. Discover the potential of our MES solution to help you optimize the use of this resource in your production plant. It is practically impossible to think of an industrial company that does not use...

Inefficiency on the shop floor: how does it affect the profitability of your business?

Digitizing and automating processes with tools like Mapex can help you boost efficiency and, as a result, the profitability of your business. Here's how an MES system is a must-have platform if you want to leave inefficiency on your shop floor behind. A fundamental...

CMMS app: a must-have solution to improve maintenance management and reduce costs

The way industrial companies manage maintenance is changing. There's no point in clinging to old methods like chasing technicians, getting bogged down with mountains of paperwork, or guessing about spare parts. Instead, provide your team with a CMMS app, which will...

‘The Toyota Way’: a practical guide to be more competitive and efficient

Do you know what the keys to Toyota's success are? Below, we summarize some of the best practices collected by Jeffrey K. Liker in his book The Toyota Way and that help us to understand why this Japanese company is a world reference in the exercise of leadership and...

How can an MES solution help you reduce rework in the manufacturing process?

Reducing the need for rework translates into lower operating costs, which is why it is worth implementing measures to address this issue. In this article we explain how an MES solution like Mapex can help you achieve your goal. Rework has a very negative financial...

Proof of concept: what is it and how do we approach it at Mapex?

Do you know what a proof of concept is? Below, we explain what this very small-scale implementation consists of and what methodology we follow at Mapex to carry it out with our MES system. In the B2B sector it is very common that, before starting the pilot project and...

Types of waste and Mapex solution for each of them

Find out what the seven types of waste according to Lean Manufacturing are and how, thanks to Mapex's MES solution, you can get a little closer to eliminating them. Industrial companies are constantly, and now more than ever, looking for ways to improve their...